PM Series 2D CNC Automatic Wire Bending Machine, 2D Wire bender

Video in Youtube: https://youtu.be/rd_qtAaL9B8

Using area:

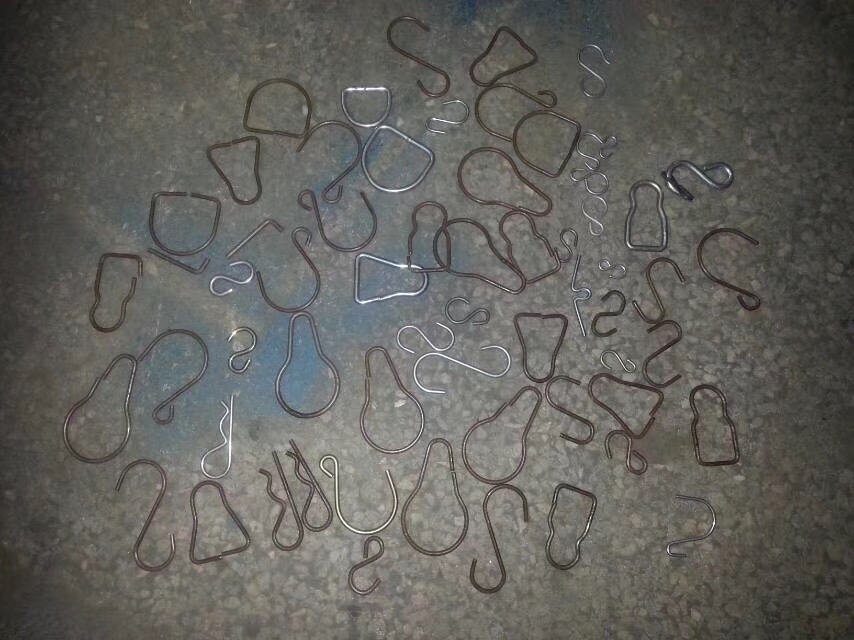

A: auto parts, automobile seat frame, door lock rod, serpentine spring, including single and double snakes, snake car cathead circlip, automobile safety belt circlip, automobile seat support wire, motorcycle parts, bicycle parts, bicycle are more suitable for production of wire forming machine;

Two, daily use hardware products: kitchen display rack, stacks, egg cradle, cupboard drawing basket, refrigerator frame, and bathroom frame steel

Silk products, supermarket shopping basket, cart, display hanger and so on.

Three, iron wire craft products, lighting line molding products, fishing gear accessories products, including red wine rack, KTV fruit bowl, Christmas each

The gifts made of steel wire are used in planes or stereoscopic parts that are made of steel wires or wires of different shapes.

Four, all kinds of cage processing: pet cage, bird cage, dog cage, cage, squirrel cage and so on.

Five, clothes hanger, shoe hang, curtain hook, shelf hook, display rack hook and so on all kinds of hooks.

General Description:

2D CNC Fully Automatic Wire Bending Machine is mainly used for bending and forming various metal wire into different shape in two-dimensional.

The wire feeding and rotary bending system both adopt servo motor,significantly improves the precision of the product, and increases the speed and flexibility of machine effectively,furthermore greatly improves the production efficiency.

According to the characteristics of wire processing, various kinds and shapes,we specially design the controlling system with a memory storage function,which can save more than 100sets of processing program for different products, can optionally select any one of them when needed.

Main Features and Functions:

1.A full range of CNC Programmable wire bending machines for two-dimensional wire bending and forming, is manufactured according to European machine standards.

2.Heavy duty mechanical structures and minimum setup requirements due to reasonably design.

3.Friendly man-machine interface, user friendly programming, easy to operate.

4.Three groups of strong feeding-wire roller subassemblies powered with a servomotor ensure accurate wire feeding and excellent straightening.

5.Automatic wire straightening, feeding, forming and recording the output amount.The wire product size and parameters and presetting quantity,can also be changed and modified during producing.

6.Available for forming and bending different diameter of steel wire,iron wire, stainless steel wire, copper and aluminum wire,also other metals,which cross-section is round, flat, square, hexagonal, etc.Widely used in the industry of wire products, fan nets, handicrafts, lampshades,and so on.

Main Technical Parameters:

| Model No. | PM2-6MM | PM3-10MM |

| Main Parameters | ||

| Input Voltage | 220V,380—415—-480V, 50/60Hz, AC,3-Phase. | |

| Wire Diameter Range | 2-6MM | 3-10MM |

| Max Wire Feeding Instruction Value | 10000MM | 10000MM |

| Mini Wire Feeding Instruction Value | 0.01MM | 0.01MM |

| Max Wire Feeding Speed | 70M/Min | 50M/Min |

| Wire Feeding Accuracy | Within 0.2mm | Within 0.2mm |

| Max Bending Speed | 100Turns/Min | 100Turns/Min |

| Bending Accuracy | Within 0.5mm | Within 0.5mm |

| Machine Dimension | L:280*W:90*H:170cm | L:370*W:120*H:180cm |

| Machine Weight | 950KG | 1500KG |

2

2